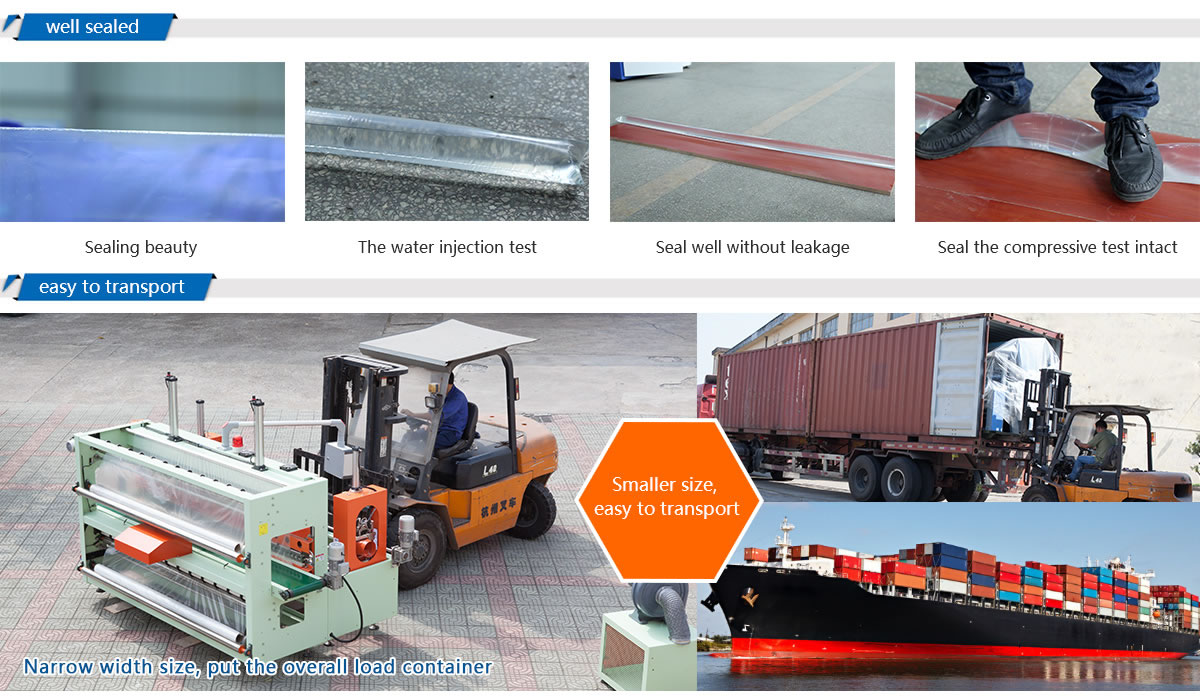

Automatic fabric inspection hot shrink packaging engineering

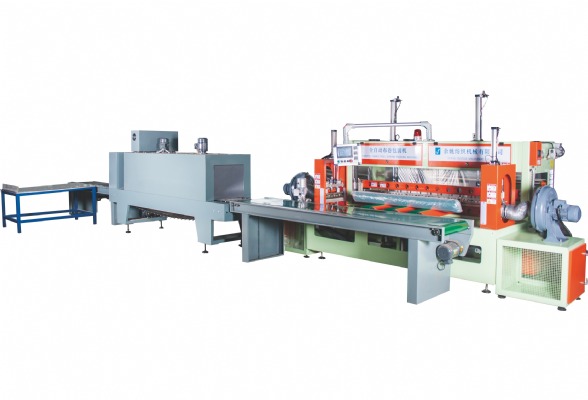

Packing Machine

Automatization is the mainstream in the development of nowadays' world. There is a gap at home in the fabric inspecting and packing engineering. The nation is dependent on importation from abroad for the needed equipment. In response to the domestic demands, our company has designed and developed this set of fully automatic fabric inspecting and packing engineering which can be applied in the supporting of almost any cloth-inspecting and rolling machines in both China and abroad to accomplish the finishing of the fabrics and also in position to construct the packing engineering series in different specifications to customers’ adherent and different functional requirements, provide them with exquisite equipment and best services.

Main Technological Process of the Packing Engineering

Accomplishes the rolling and inspecting procedures from the cloth-inspecting and the cloth-rolling.

Accomplishes the batching and color separation from the cloth inspecting, rolling to the cloth storage conveyor.

Finishing the cloth-storage engineering is followed by automatic entry into the cloth-belt conveyor;

The cloth-feeding belt conveyor carries the cloth Into the PE film automatic packing machine for the automatic packing procedure;

At finishing the packing, the cloth is carried from the middle section belt conveyor to the end section belt conveyor;

The end belt conveyor carries the packed cloth to the thermal shrinkage machine;

The thermal shrinkage machine contracts the PE film from all sides to attain a compact and neat packing;

The cloth exit roller conveyor cools down the finished product after being shrunken and carries the cloth to the cloth storage table.

The cloth storage table gives a second cooling to the shrunken product and a short time storage on itself for the cloth rolls that are still not stacked, yet

Note: The number of both the cloth feeding conveyor and the storage. Conveyor is subject to the customer' s requirement.

Main Device Layout of the Packing Engineering

Inspecting-rolling machines:4-8 units

1 unit of fully automatic PE packing machine

Cloth-introduction belt conveyors:4-8 units

Cloth-exit belt conveyor: 1 unit

Thermal shrinkage machine: 1 unit

900 rolling conveyance cloth turning machine: 1 unit Cloth turning

table: 1 unit

For the.-marked items the number of composition depends on the actual need. Each unit of the fully automatic PE packingmachine performs a monthly output as much as 8 million metres

| Main Composing Equipment Specifications: |

|---|

| ◆ Packing machine dimension :( L×H×W ) 4000mm×2250mm×2000mm ◆ Heat-Shrink machine dimension :( L×H×W ) 3500mm×1700mm×800mm ◆ Packing speed : 5-7 rolls / min max. ◆ Applicable packing range : Rolling diameter : Φ100mm~600mm Circular roll length :900~2400mm Sheet rolling size :Thickness lower than 300mm ◆ Power : a.3-phase 380V b. Packing machine master unit total power : 11kw ( actual power 6 kw ) c. Thermal shrinking machine power : 26 kw ( actual power 11 kw ) d. Roller conveyor : 0.18kw e. Belt conveyor : 0.18kw ◆ Compressed air : a. Pressure 5-7kg / cm2 b. Air amount : 0.5m3 / min ( equivalent to 5HP air-compressor ) ( Power and air supply are to buyer's preparation ) |